Digital transformation in manufacturing is coming your way. So is Industry 4.0, Smart Manufacturing and the Internet of Things (IOT). These often-overlapping concepts are all aimed at applying digital technology to enhance your ability to see and react more quickly to changing conditions within your company and across your value chain.

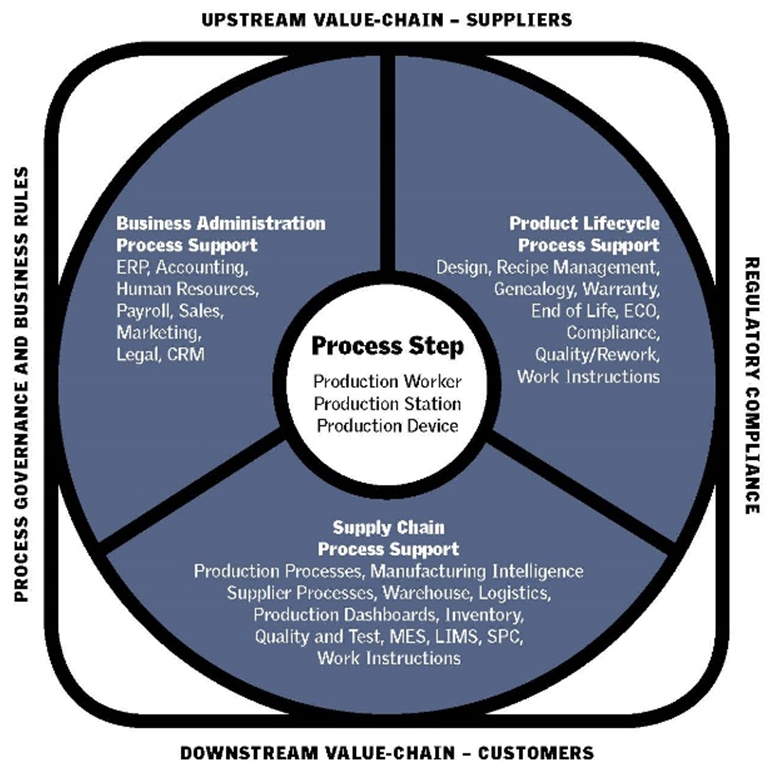

Manufacturing enterprise information can be viewed as three information segments as shown here.

The administration category represented by ERP, CRM, Legal, etc. is a very well-integrated set of business processes. The functionality of the product lifecycle category is another highly integrated set of tools regarding product design to end of life. Then there is the aggregated group of information resources in production facilities where we typically have over one hundred standalone information silos in each plant.

While the admin and product information resources are highly integrated, the operations segment is anything but. The digital transformation opportunity is to align manufacturing and value chain data resources into a connected set of your existing interoperable data nodes. This is possible through our concept of Production Process Management, a product-driven approach that can deliver and/or retrieve data to link every information resource directly with the instance of a production order at a production step. Digital transformation made easier.